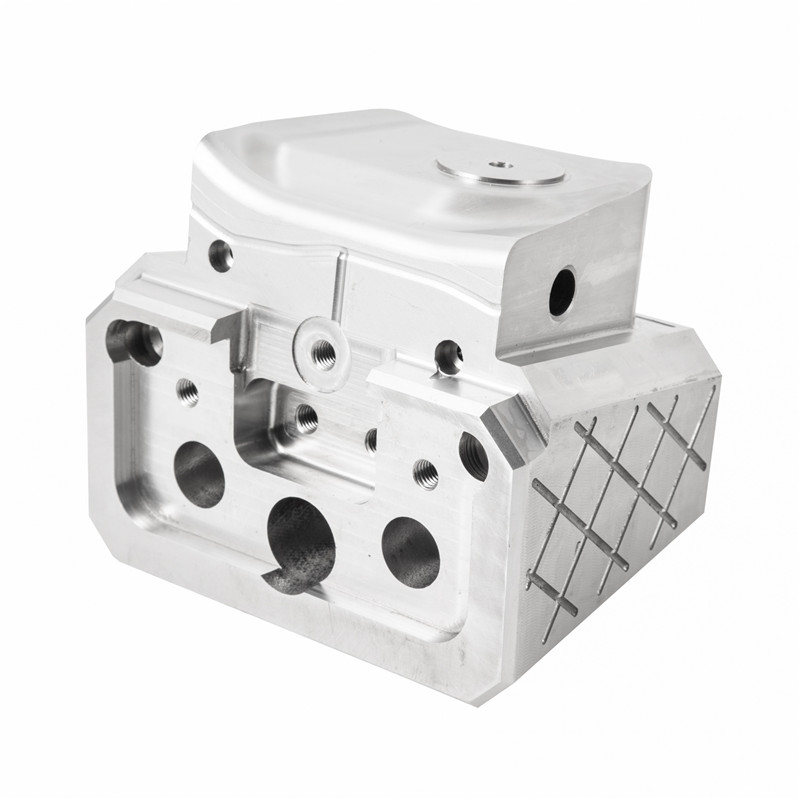

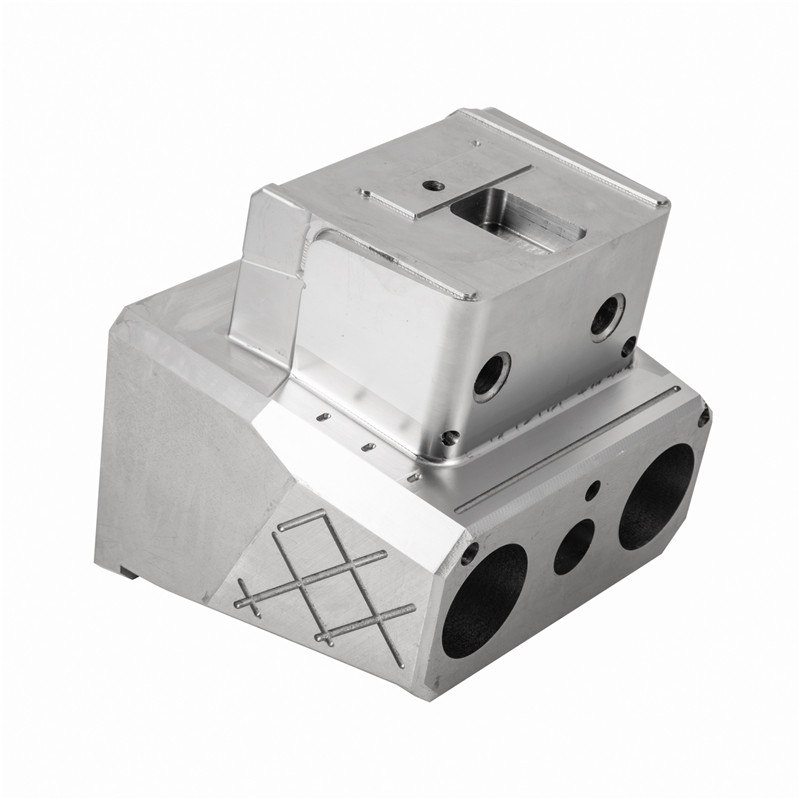

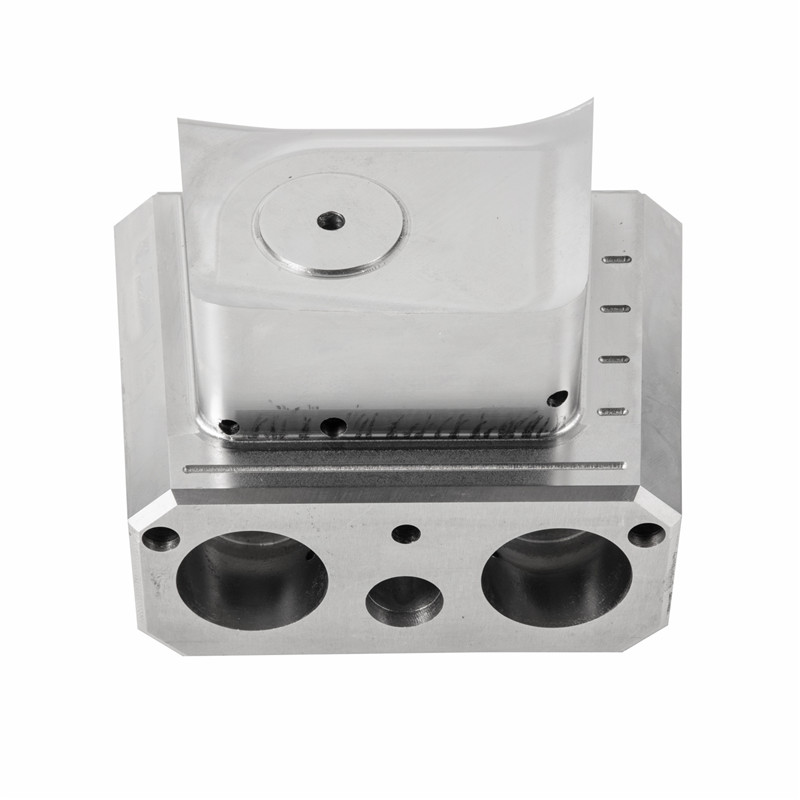

Isilayidi esinembayo esiphezulu sesikhunta se-die casting kanye nesikhunta sokujova

Material / Steel

I-Kunshan BCTM ingahlinzeka ngezinto zasendaweni ezingabizi kakhulu ngokusebenza okuhle kakhulu, okuzuze ukuqashelwa konke kwamakhasimende ethu.Futhi singahlinzeka ngensimbi engenisiwe evela kumikhiqizo ehlukene emhlabeni wonke, njenge-ASSAB, Schmiedewerke Gröditz, Hitachi Metals, Schmolz+Bickenbach, Finkl Steel, Scana, Crucible, Posco, Doosan, Daido Steel, Koshuha Steel, Sanyo Steel, Nachi , Sinto, Saarstahl, Buderus, Kind & Co, Aubertduval, Erasteel, Sorel forge, njll.

Ukukhiqiza

Sinemishini esezingeni lomhlaba yokwenza ukugaya, ukugaya, umshini we-CNC, i-EDM, ukusika izintambo, ukugaya ngesivinini esikhulu, njll. Izinga lethu lihle kakhulu futhi lizinzile.Ngaphandle kwemishini yesimanjemanje, sinethimba lezobuchwepheshe elinolwazi kanye nethimba lokukhiqiza.Bonke okungenani banesipiliyoni seminyaka eyi-18 sokusebenza.Bangathola ngokushesha nangokucacile izidingo zekhasimende.Umuzwa wabo ocebile ungasiza amakhasimende ukuxazulula azuze ukuqashelwa kumakhasimende ethu.

Izinhlobo zokukhiqiza:

Izisetshenziswa ze-CNC: Isivinini esiphezulu se-CNC esiqondile M/C's.

Sink EDM.

Izintambo ze-EDM.

Amathuluzi ahlukahlukene omshini wezandla.

Izinhlobo ze-CNC.

Spotting press.

Ama-grinder angaphezulu.

Imininingwane Umdwebo

Ithambile Siyisebenzisa

UG, AUTO CAD

I-Tool Design

I-Kunshan BCTM Co., Ltd. isebenzisa indlela enezigwegwe eziningi ekwakhiweni kwamathuluzi okuhlanganisa ochwepheshe bethu bamathuluzi, umklami wamathuluzi kanyeochwepheshe benqubo.

• Ukuqinisekiswa kwedizayini yamathuluzi kusetshenziswa isofthiwe yokulingisa ukugeleza kwe-Mold ukuze kugcwaliswe ukufa, ingxenye ye-thermos kanye nokuhlaziywa kwe-FEA.

• Buyisela emuva ubunjiniyela bamathuluzi ukuze udale idizayini ngefomethi yokuqina.

• I-CAD: I-Unigraphics, i-AutoCad, isofthiwe ye-Mold flow.

Ukuhlola

Izisetshenziswa Zekhwalithi

Qondisa Umshini Wokulinganisa onesixhumi esibonakalayo se-CAD.

I-Shadowgraph.

Umhloli wokuqina.

Ama-plug and Thread gauges.

Ukuqaliswa Kwesistimu Yekhwalithi

• Ukusetshenziswa Kwesistimu Yekhwalithi, okuhlanganisa i-ISO 9001\2005 ebhala Incwadi Yekhwalithi, Izinqubo kanye Nemiyalo Yomsebenzi.

• Ukuphathwa Kwephrojekthi ngokusebenzisa izidingo zeKhasimende.

• Nikeza imibiko enobukhulu njengoba kudingwa Amakhasimende.

• Nikeza izitifiketi zezinto ezibonakalayo njengoba kudingwa Amakhasimende.

• Ekucushweni nasekuhlolweni kokugcina ngaphambi kokupakishwa nokuthunyelwa.

Uma impahla ifika efekthri, sizohlola ubulukhuni, ukutholwa kwamaphutha, ubukhulu nezinye izinto ukuze siqiniseke ukuthi yonke into ilungile.Sisebenzisa ukuhlolwa kwenqubo ukuze sizame ukuthola izinkinga ngokushesha ngangokunokwenzeka ukuze songe isikhathi futhi sigweme ukulahlekelwa kwezindleko ezinkulu.Ngemva kokuphela kokukhiqiza, sizohlinzeka ngombiko we-CMM.