Ngobuchwepheshe ekuklameni nasekukhiqizeni isikhunta se-die casting

Isingeniso Somkhiqizo

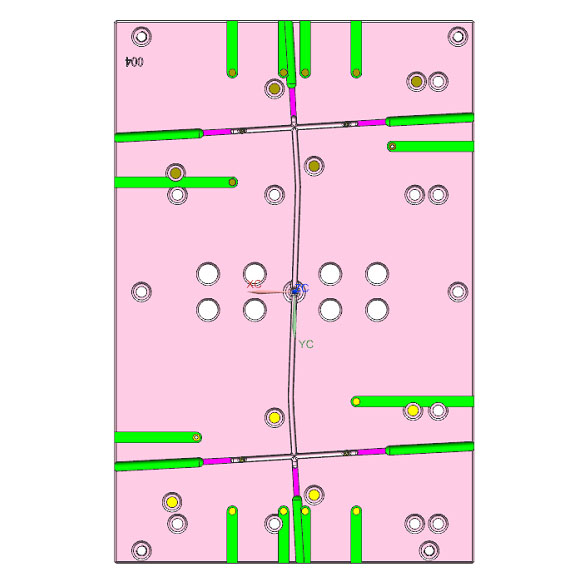

Isofthiwe Esiyisebenzisayo:

I-CAD\CAM:I-Unigraphics, i-AutoCad

Izisetshenziswa ze-CNC:

Isivinini esiphezulu se-CNC esiqondile M/C's

Sink EDM

Izintambo ze-EDM

Amathuluzi ahlukahlukene omshini wezandla.Izinhlobo ze-CNC.Spotting press.Ama-grinder angaphezulu.

Ukuhlola:

Qondisa Umshini Wokulinganisa onesixhumi esibonakalayo se-CAD.

I-Shadowgraph.

Umhloli wokuqina.Ipulaki

Izikali zochungechunge.

Okubalulekile:

Insimbi yendawo engabizi kakhulu

Izinto ezingenisiwe

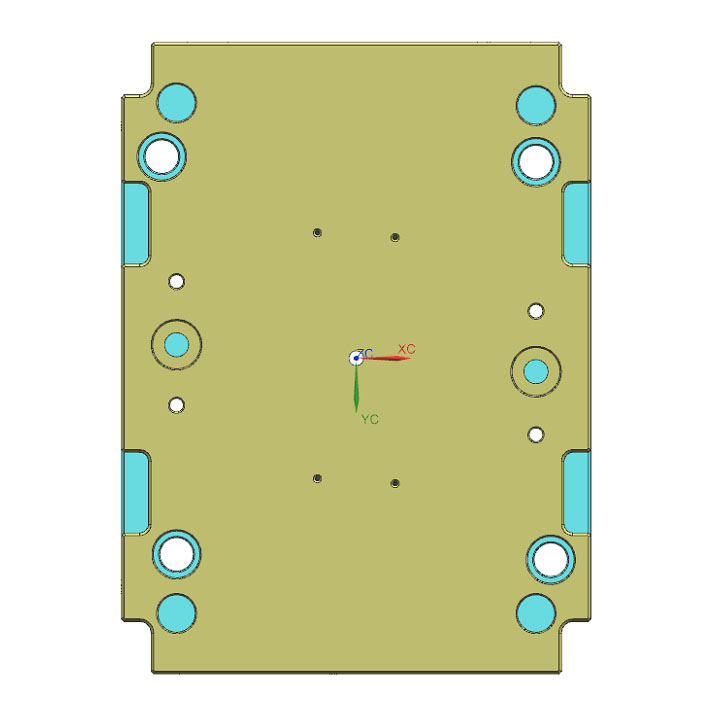

Imininingwane Yomkhiqizo

Isibonisi sophahla oluhlotshisiwe

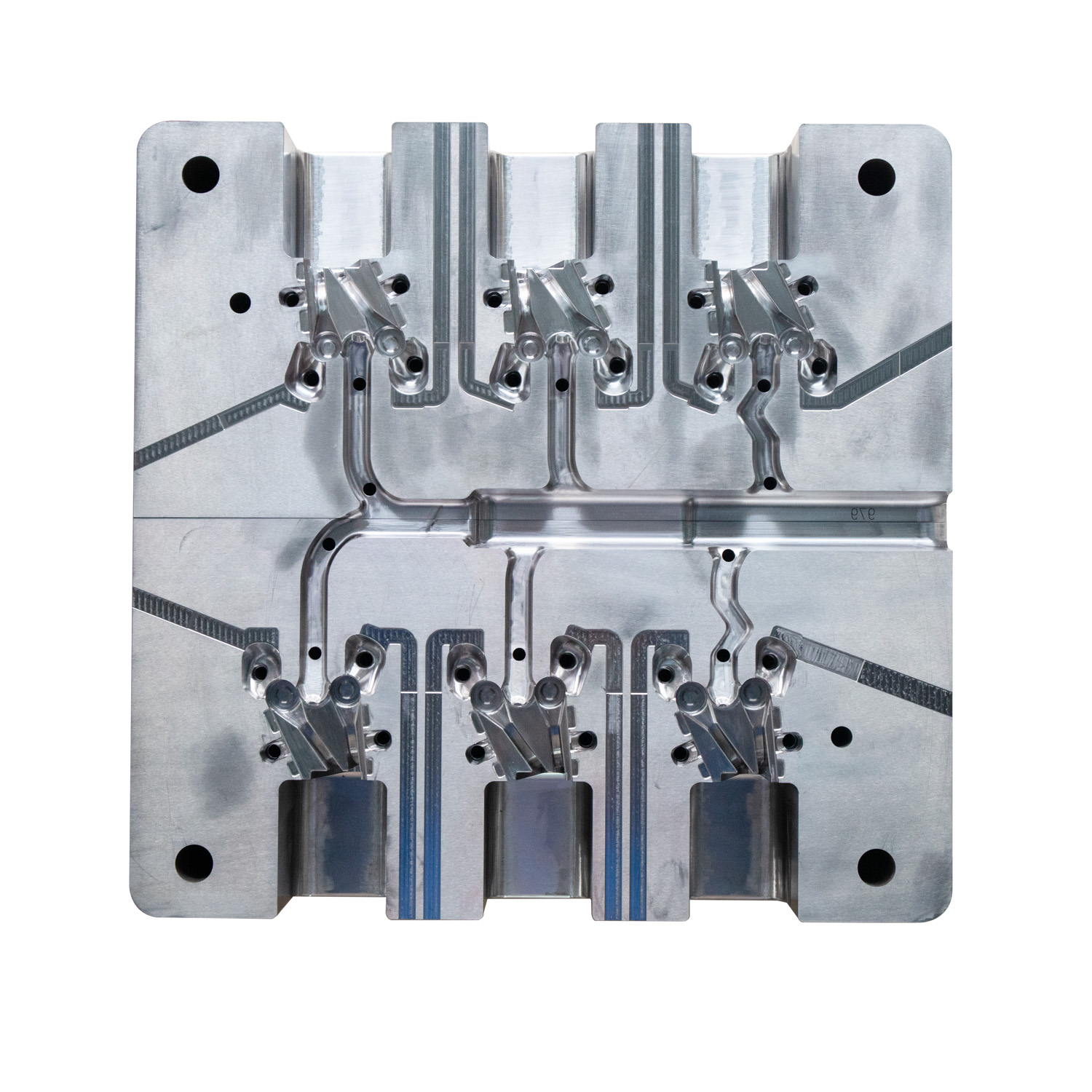

Uma kunezimbobo/amabhakede ngaphakathi noma ngaphandle komkhiqizo, kubalulekile ukuklama indawo engaphezulu etshekile

Izici zophahla oluthambekile:

Ingaphezulu elithambekile lishayelwa i-ejector pin plate ukuze kukhishwe umkhiqizo.

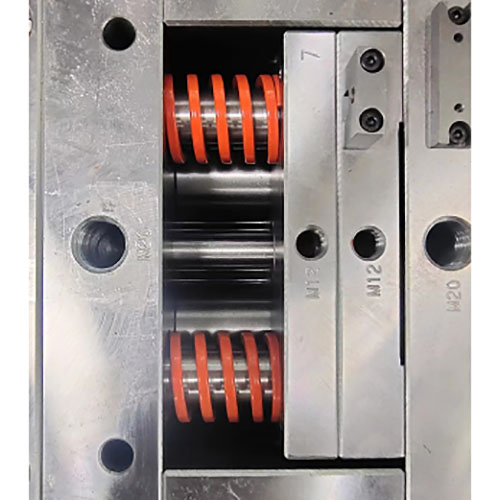

Izici ze-Parallel block: thuthukisa ukuzinza komkhiqizo ngesikhathi sokubunjwa komjovo.

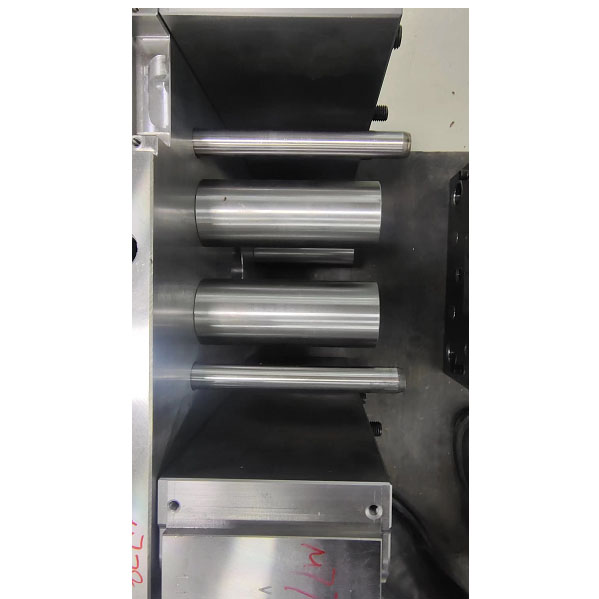

Izici zensika yomhlahlandlela wesikhunta: isiqondiso, umsebenzi wokumisa.

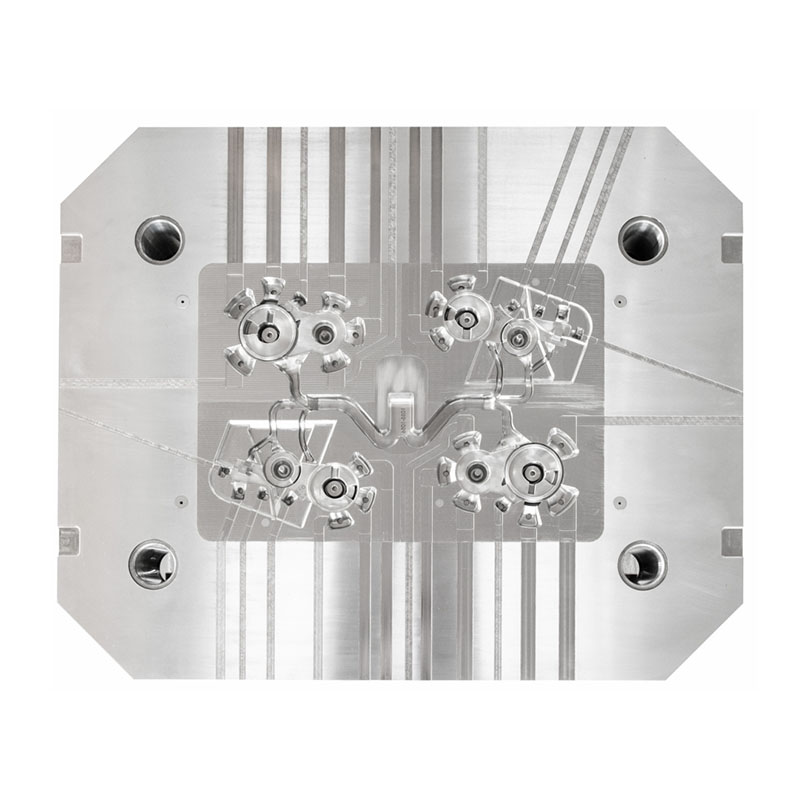

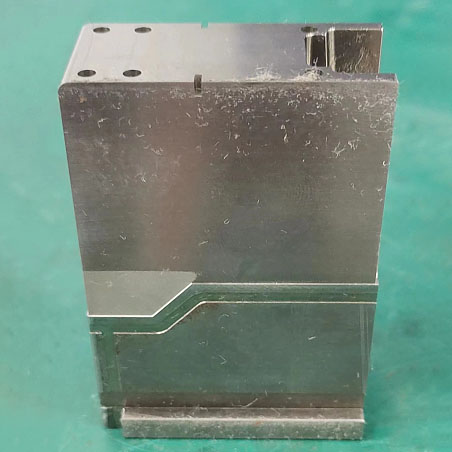

Izici zesilayidi:

Lapho uvula futhi uvala isikhunta, insika yomhlahlandlela ethambekele yesikhunta sangaphambili ishayela isilayidi, ngaleyo ndlela ibangele ukubunjwa nokuhlukaniswa kwesakhiwo somkhiqizo.

Izici zebha yesilayidi: isilayidi esingashintshi, inkomba yesilayidi.

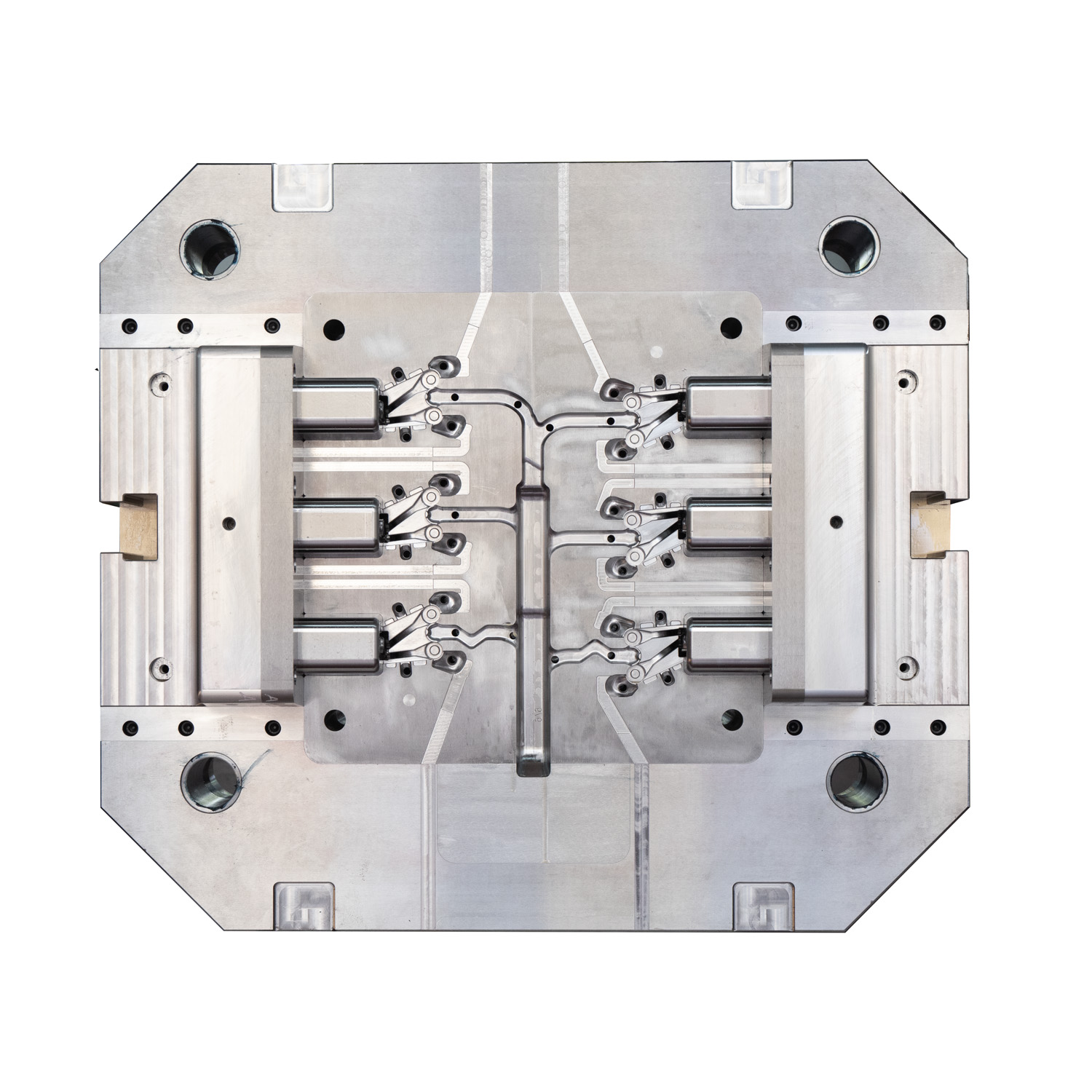

Isivalo sangaphandle

Ngokuvamile isetshenziswa ekubunjweni kwamapuleti amathathu noma isikhunta sabesilisa esinamapuleti aphusha.

Izici ze-mold shutter yangaphandle

Isifanekiso sowesifazane sishayela ipuleti lokusunduza lesikhunta ukuze liwukhiphe kahle umkhiqizo ngemva kokuba okufakiwe kwesikhunta sowesilisa kuhlukaniswe kumongo wesikhunta.

Isivalo sikaZibuthe

Ngokuvamile isetshenziswa isikhunta ezintathu plate

Izici ze-shutter magnetic

Isifanekiso sowesilisa sishayela isifanekiso sesifazane ukuthi sisuke epuletini, ukuze induku yento yokugeleza inganqanyulwa kahle.

Izici zebhulokhi yesilungiselelo esihle

Qinisa ukulawulwa kokunemba kokuma ngemva kokuvala isikhunta.

Izici ze-ejector plate spring

Isenzo sokubuyisela ipuleti le-ejector

Izici zekholomu yokusekela

Ukuzinza komkhiqizo ngesikhathi sokubunjwa komjovo

Faka isibonisi

1. Umkhiqizo unezimbambo ezijulile noma izakhiwo ezinodonga oluncane ezidinga ukuklama okufakiwe

2. Isakhiwo esivamile semikhiqizo eminingi singaklanywa kuphela ngokufaka okufanayo uma kunomehluko ezindaweni ngazinye

Faka izici

Ukulawula kokukhipha/ukucubungula okulula, ukushintshwa kalula.

Isibonisi sokufakela yenaliti

Faka izici

Kulula ukukhipha/ukucubungula ukulawula/ukulungiswa kosayizi, ukushintshwa kalula.

Isibonisi sebhodi ezintathu

Izici ze-stripper plate

I-runner rod ikhishwa futhi ikhishwe yi-stripper plate.

Izici zepuleti lomgijimi

1. Ukucubungula okulula

2. Izinto eziqinile zingakhethwa ukuthuthukisa impilo yesevisi